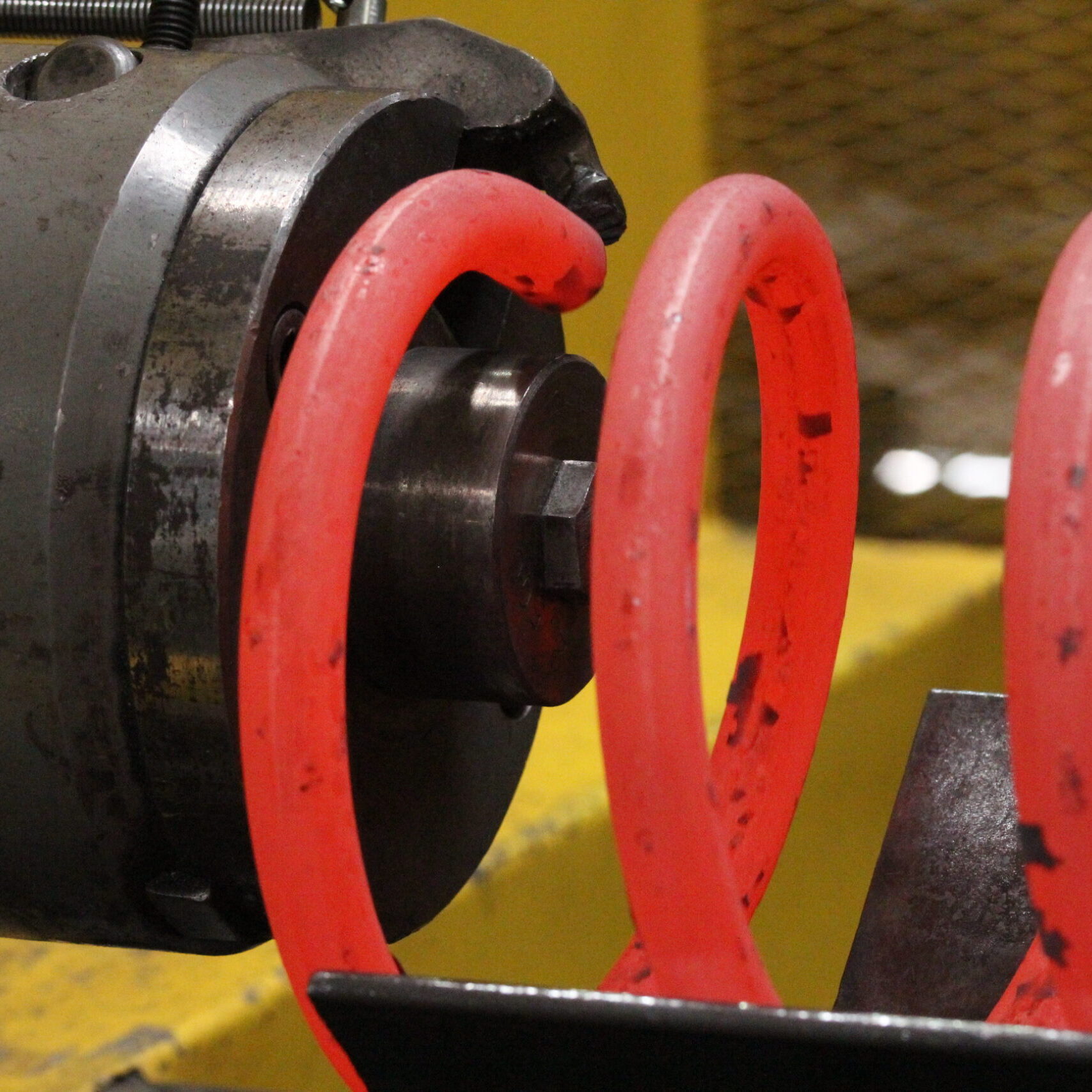

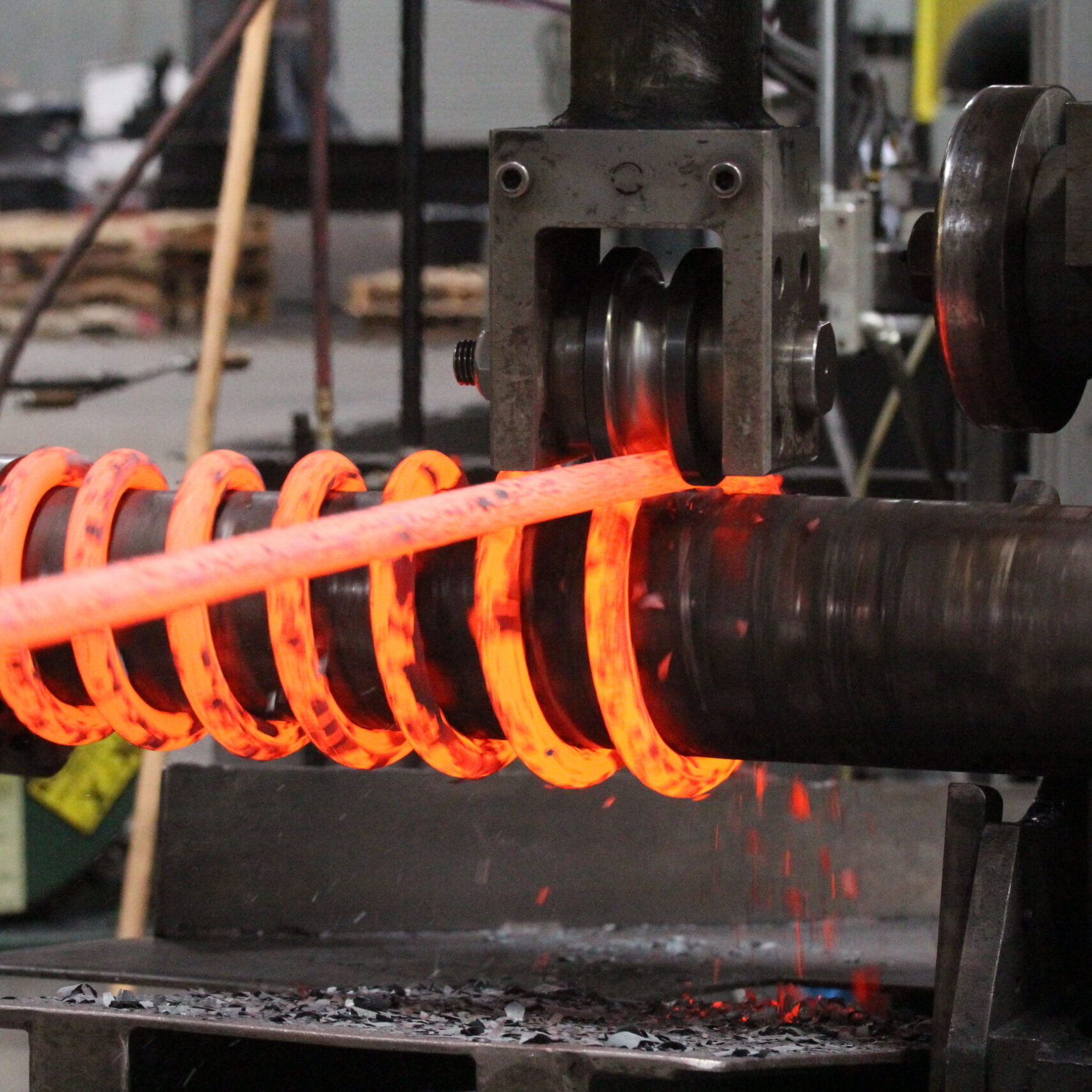

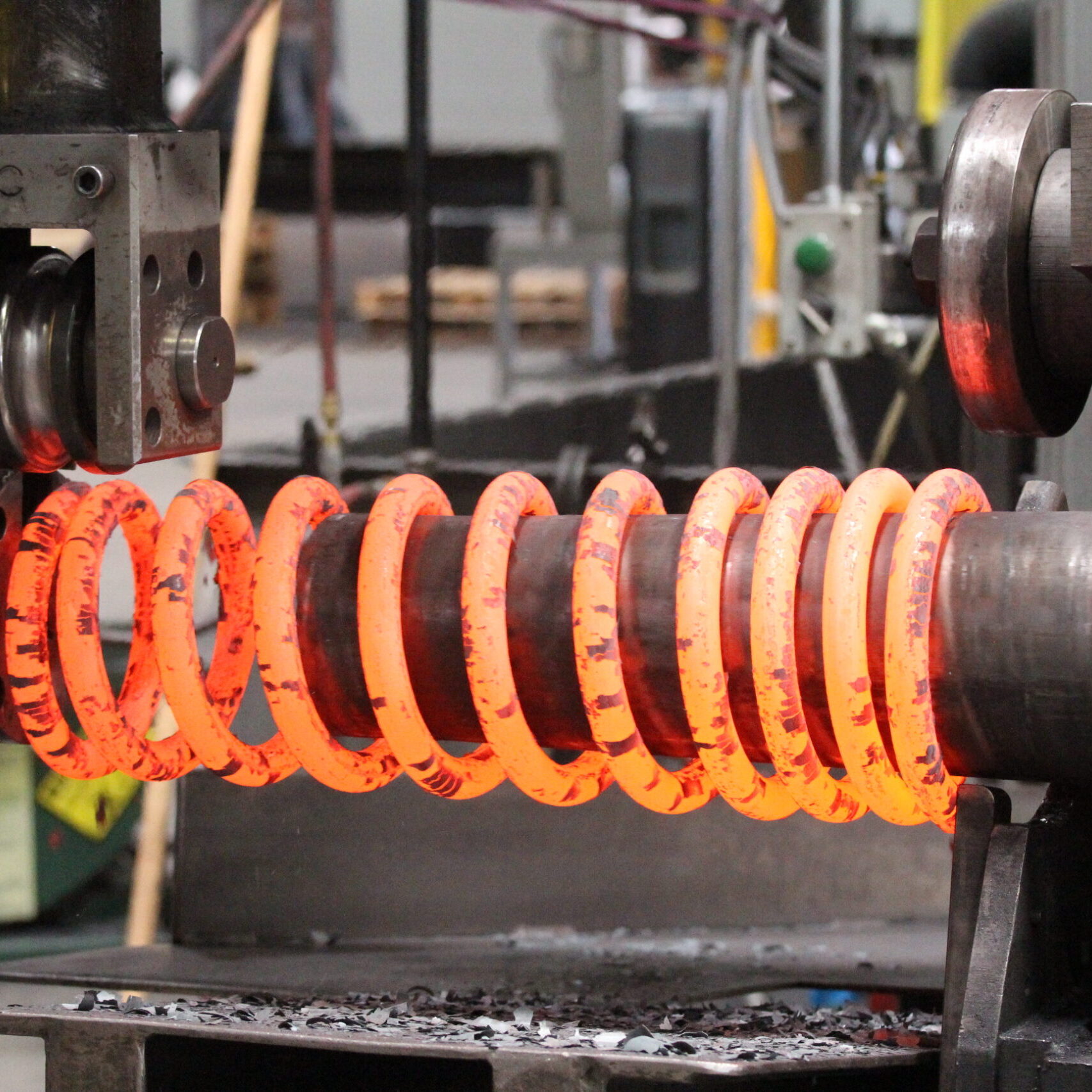

THE HOT WOUND COIL SPRING MANUFACTURING PROCESS

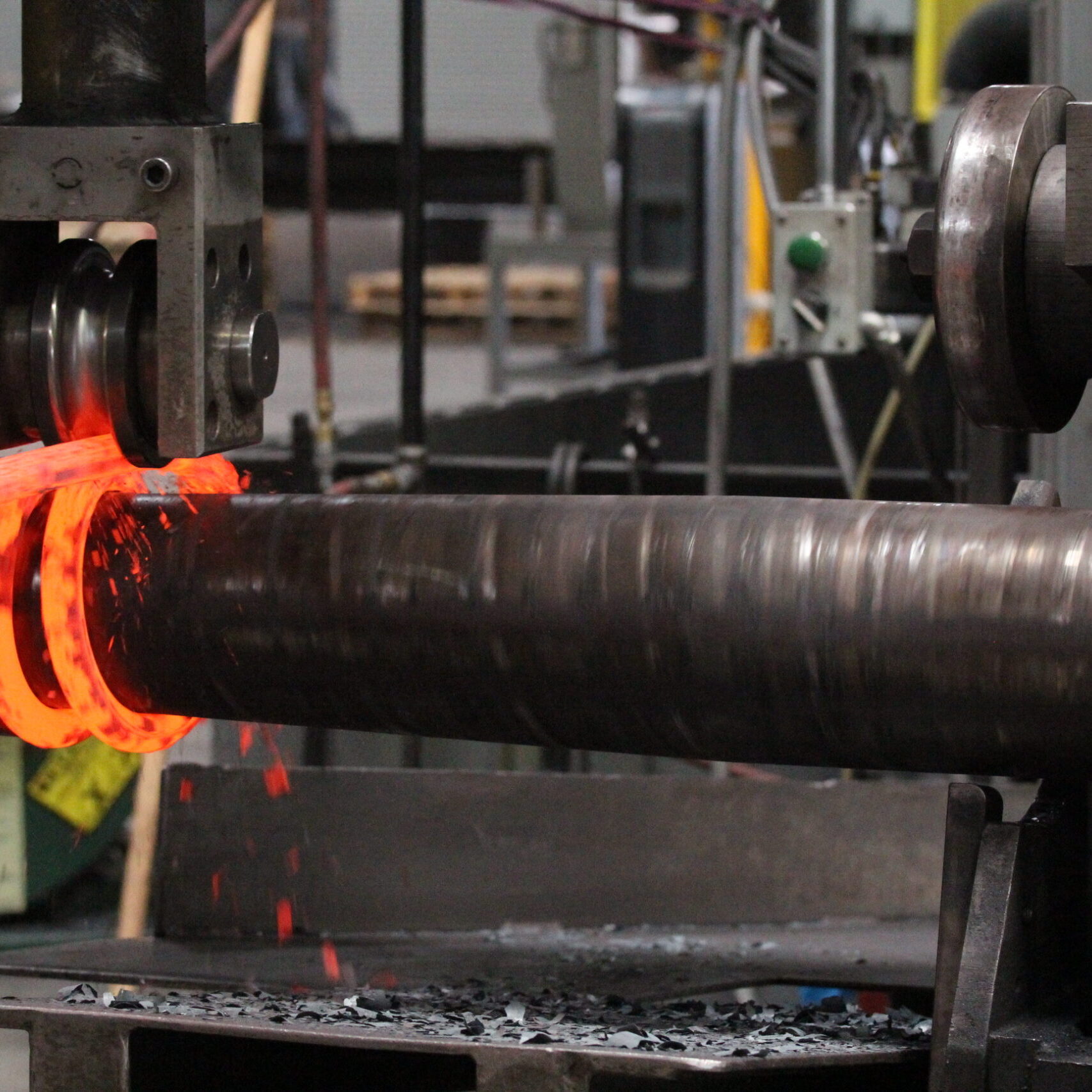

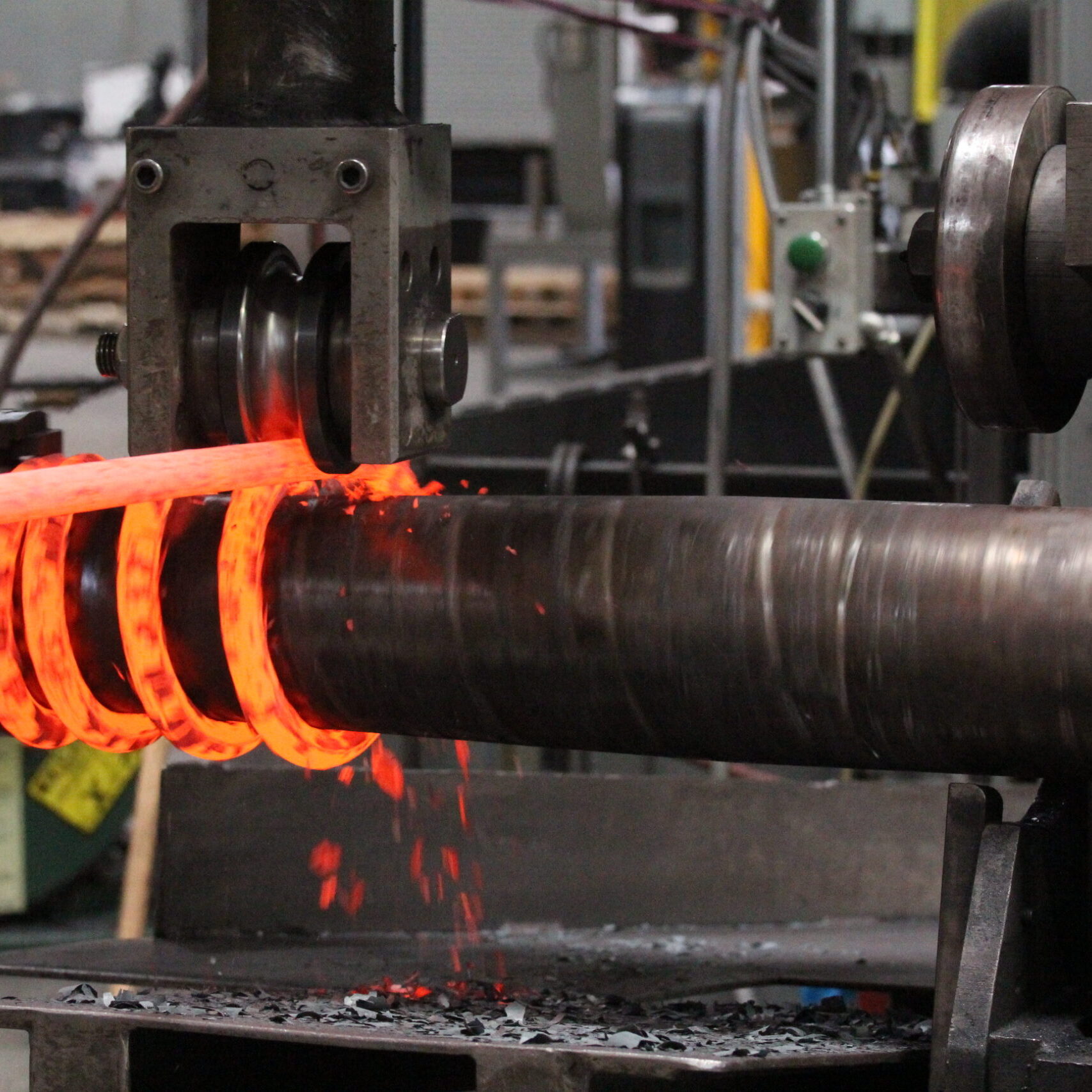

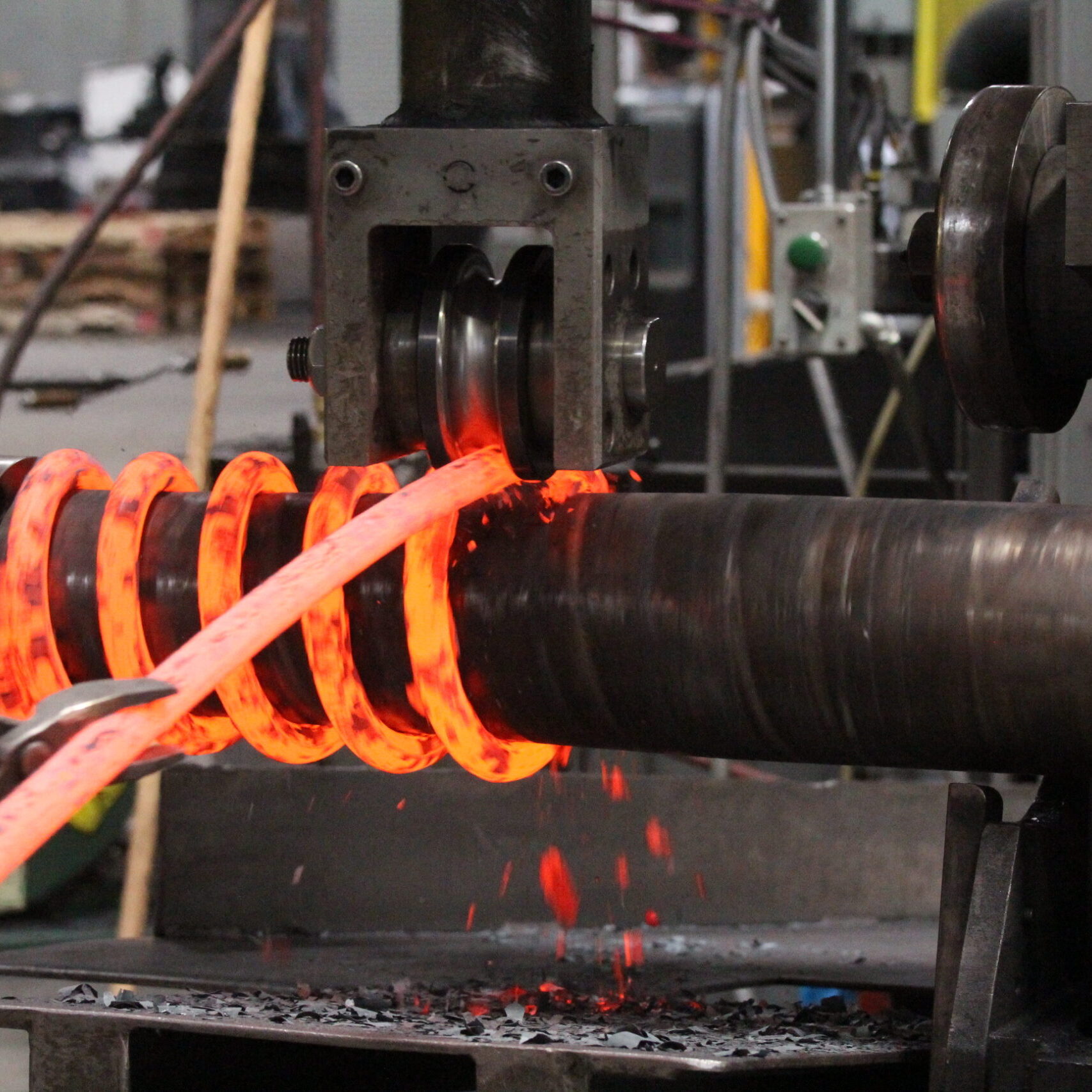

At the core of Betts Spring hot wound coiling system is an energy-efficient, drastically low emission, walking beam furnace. This furnace can reach temperatures of 1750°F and move .562″ to 1.75″ material through in a consistent and automated manner.

At the core of Betts Spring hot wound coiling system is an energy-efficient, drastically low emission, walking beam furnace. This furnace can reach temperatures of 1750°F and move .562″ to 1.75″ material through in a consistent and automated manner.

The furnace meets stringent California emissions standards and provides the ability to improve production output over previous systems. Using advanced technology, the furnace’s energy usage was taken from 12MM BTU/hour to only 1.65MM BTU/hour. A significant savings and gas consumption at almost 50% of permitted levels.

This coiling process can produce a variety of hot wound springs and vibratory springs to meet your project and specifications.

BETTS HOT WOUND SPRING MANUFACTURING CAPABILITIES:

- Grinding & shot peening

- Coiling material diameters range from .500″ to 1.750″

- Fully automated continuous flow Hot Wound coil line processes over 125 tons of steel per month

- Single piece flow according to Lean Manufacturing concepts